http://www.viclite.com

Home Astralux << 1 2 3 4 5 6 7 8 9 10 11 12 >> Aquarium Lamp Email Us

![]()

Astralux Quality Process

ASTRALUX 'S SUPERIORITY OVER LOW QUALITY PRODUCTS

What makes a good lamp???

Three vital ingredients of a good lamp are the three M's

MATERIAL MAN MACHINE

MATERIALS

There's an age old saying 'As you so sow, so shall you reap'. The quality of a lamp will always be dependent on the quality of components that go into its making. Astralux , with its very strong vendor development department in conjunction with a very well equipped quality department ensures that only the best goes into lamps coming out of the factory.

Components can be classified into two parts.

i) components that go into the making of a ballast.

ii) components that form the capsule.

CAPACITOR: In self-ballasted units, the ballast forms the heart of the lamp with the electrolytic capacitor being the most critical unit. There are only 3 companies the world making electrolytic capacitors with 5000 hours rated life at 105 Celsius which translates into a life span of over 10,000 hours for the lamp. Unlike low quality manufacturers, Astralux, sources its capacitor only from one of these sources. The picture above shows a capacitor sourced from Panasonic used by GAL on the right and a capacitor with unknown rated life typically used by low quality manufacturers.

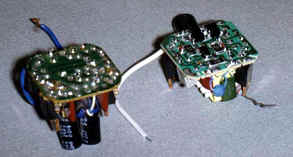

BALLAST: The entire ballast goes into a relatively small plastic housing where during operation the temperature can rise to as high as 90 degrees Celsius. The picture shows a low quality ballast with components mounted on one side of the PCB. The heat generated by this high density of components is tremendous and results in premature heat related failure of the ballast. On the far right is a ballast made by Astralux that has virtually no crowding of components thereby eliminating the risk of heat failure. Astralux achieved this by using Surface Mounted Devices (SMDs) that enable both sides of the PCB to be used. In addition to elimination of heat related failures, being precision components, the reliability of SMDs with respect to their ratings is much higher.

TORROID: Astralux uses a polyester coated core for its torroid. This eliminates the need of using plastic insulated wire used by the low quality manufacturers. At high operating temperatures the insulation gives way resulting in the failure of the torroid and thereby an early failure of the lamp. The grade of the ferrite core used by Astralux has very stable operating parameters at high temperatures.

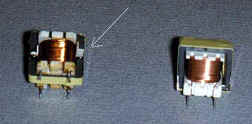

CHOKE: A major difference in the choke used by low quality manufacturers and Astralux, is the core used in the construction of the choke. Far eastern manufacturers use a 'spacer' to adjust the air gap for achieving correct wattage. With heat this wedge loosens. This results in the choke starting to "chatter" which results in very high wattage of the lamp ultimately ending with the burnout of the lamp. Astralux (pictured right) uses a pre-gapped core of high temperature grade eliminating the need for a 'spacer' and its related failures.

SOLDERING: Soldering plays a very critical role in the long term performance of the ballast. Poor soldering , brought about by manual applications generally results in a dry solder condition resulting in the solder falling off and the contact opening up again resulting in the failure of the ballast. Astralux uses state of the art wave soldering machines, which perform this automatically. This results in uniform soldering, the correct amount of flux and solder and eliminates dry solder condition. The picture above shows the soldering condition of a low quality lamp. The picture on the right shows the difference in the soldering of the two ballasts.

SWITCHING POWER DEVICE: Astralux uses switching devices in which operates narrow band and are matched. This is possible due to the procurement of such devices from reputed manufacturers like Motorola/IR/SGS. Low quality manufacturers generally use these devices which originate from unknown sources

PRINTED CIRCUIT BOARD: Astralux uses PCB of right thickness of material conforming to UL 94 V0 rating. This ensures that the PCB tracks are able to retain its properties over the entire lifetime of the lamp. These PCB's are fire retardant and provide safety to the user. Low quality manufacturers generally use lower thickness and low-grade material resulting in PCB deformation owing to thermal shocks and this entails track damage. Generally this material is not fire retardant thereby posing a fire hazard to the user.

COMPONENTS THAT FORM THE CORE:

1) Glass and Coating Material: -

Astralux uses an environment friendly glass that has low sodium content and also use protective coating on the glass, which arrests the release of sodium from the glass and helps in maintaining lumens. Sodium is poisonous and highly reactive to Mercury and Tri band phosphor, hence it is necessary to prevent interaction between the two. Low quality manufacturers use poor quality glass tubing, which has high soda content, and are also unaware of the usage of protective coating.

2) Tri Band Phosphor: -

Astralux uses tri band phosphor from Europe, which produce 15%-40% higher lumens with lumen depreciation at 2000hrs of about 15% while the low cost products have a lumen depreciation of 25-35% at 2000hrs. Astralux does not recycle the waste phosphor while small makers recycle it many times. The recycling has negative impact on the lumen and lumen depreciation.

3) Emitter: -

Astralux uses emitters from Japan and are able to automatically control the emitter retention weight on the cathode. Further the cathodes are imported from Philips Europe, for which the emitter application is correctly and precisely controlled. Emitter is one of the most important points, which controls the lamp life in normal switching on off application.

4) Gas Mixture: -

Astralux uses special high quality gas mixture in the lamp and also control the gas pressure precisely on the higher range in order to achieve the specified lamp life

5) Glow Starters: -

Astralux uses glow starters from Europe and America, which are of very high quality and have steady starting characteristics that helps in quick and efficient starting of the lamp. Most of the low quality makers are using poor quality starters, which have short life and very inconsistent starting characteristics because of lower rated voltages. The switching cycle life of our starters exceeds 50000 switching cycles while most of the low quality lamps have very low switching cycle life, typically between 500-2000 cycles.

6) Plastic Components: -

Astralux uses plastic components, which are UV stabilized and fire retardant; hence they do not lose their strength and colour over its life, are safer and comply with international safety standards.

____________________________________________________________

MAN

Astralux employs the services of the best in the trade facilitated by a liberal approach of the authorities where there are no restrictions to hire personnel of any nationality. This enables Astralux to pick and choose from a wide selection of available manpower resources.

____________________________________________________________

MACHINE

Astralux has over the years developed the expertise to fabricate and commission lamp-making lines. This enables us to design and modify machines relatively easily to suit various requirements.

_____________________________________________________________

TEST REPORTS

Astralux lamps are tested by independent Test houses such as RWTUV of Germany. UL and ULC, TCA Australia Rowland Laboratories of UK and EMC Test Laboratories. All of these testify to Astralux's claim of superior quality lamps. Most low quality manufacturers' claims are self-declarations without certifications

__________________________________

_____________________________________

__________________________________